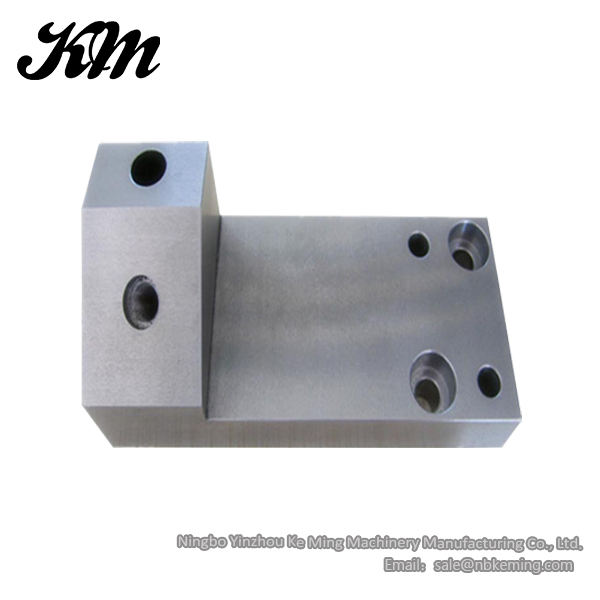

Ningbo Yinzhou Ke Ming Machinery Manufacturing Co., Ltd. is a leading supplier, manufacturer, and factory of Inconel precision casting in China. We specialize in producing highly accurate, detailed, and complex shaped components using the lost wax casting process with Inconel alloys, such as Inconel 625, Inconel 718, Inconel 713, and Inconel 792. Inconel precision casting products are widely used in various industries, including aerospace, automotive, petrochemical, marine, and defense.

Our skilled team of engineers and technicians has extensive experience in Inconel casting, and we use advanced technology and equipment to deliver high-quality products with exceptional consistency and zero defects. Inconel casting has excellent strength, corrosion resistance, high-temperature resistance, and wear resistance, making it an ideal material for demanding applications.

If you need Inconel precision casting components, we can provide customized solutions based on your specific requirements. Trust Ningbo Yinzhou Ke Ming Machinery Manufacturing Co., Ltd. as your reliable partner for all your Inconel casting needs. Contact us today to learn more!