Sand Casting - The Essential Process for Manufacturing Complex Components

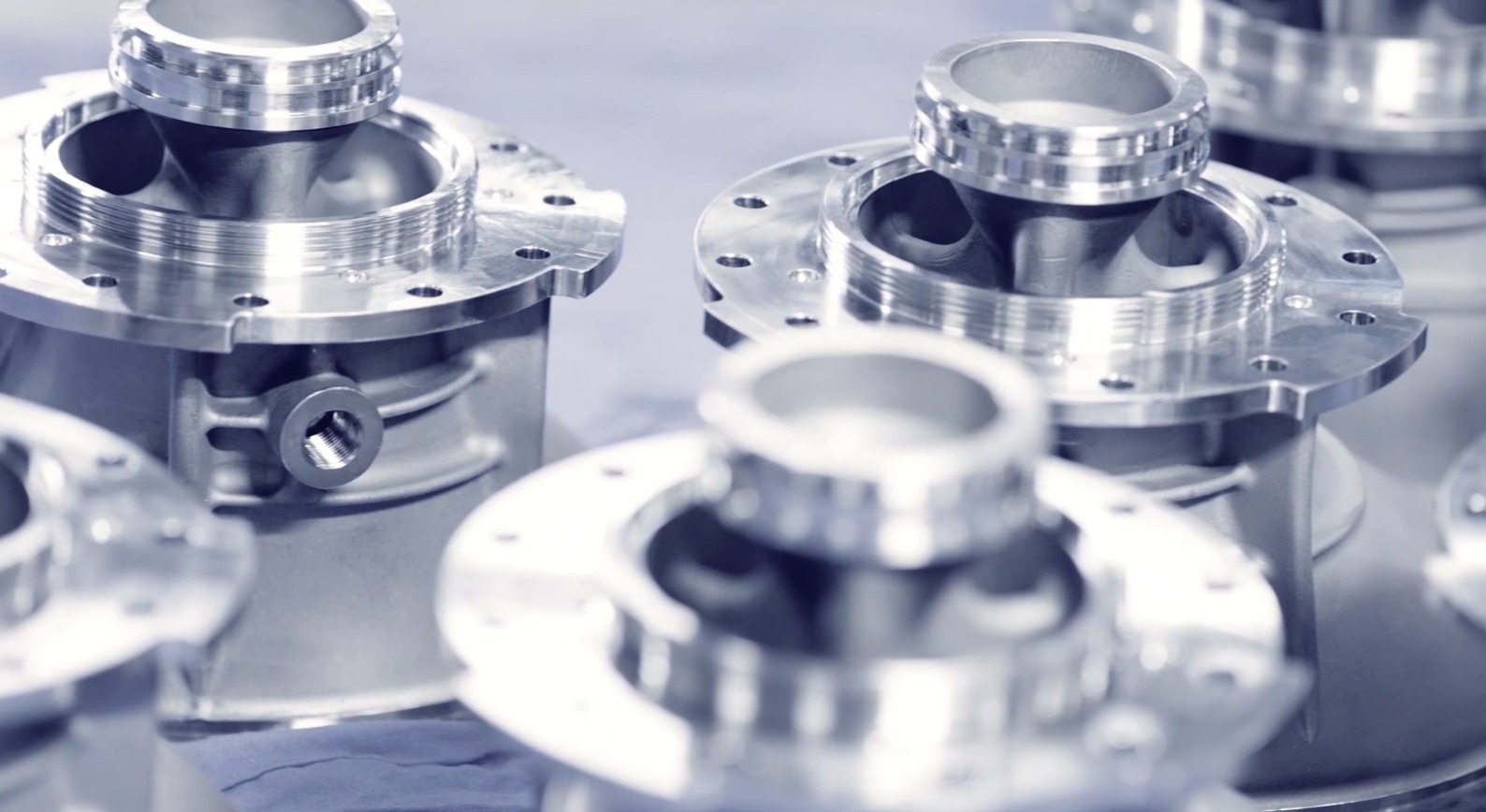

Sand casting is a widely used process for the manufacturing of complex and high-value-added components. The process involves pouring molten metal into a mold made of sand, which solidifies to create a solid metal component. The sand casting process is ideal for creating large and intricate parts that would be difficult or impossible to produce using other manufacturing methods. Ningbo Yinzhou Ke Ming Machinery Manufacturing Co., Ltd., specializing in the manufacturing of lost wax investment castings and finished products in carbon steel and low alloy steel, is a supplier of investment castings with water glass process in China, meeting the demands of numerous industries.

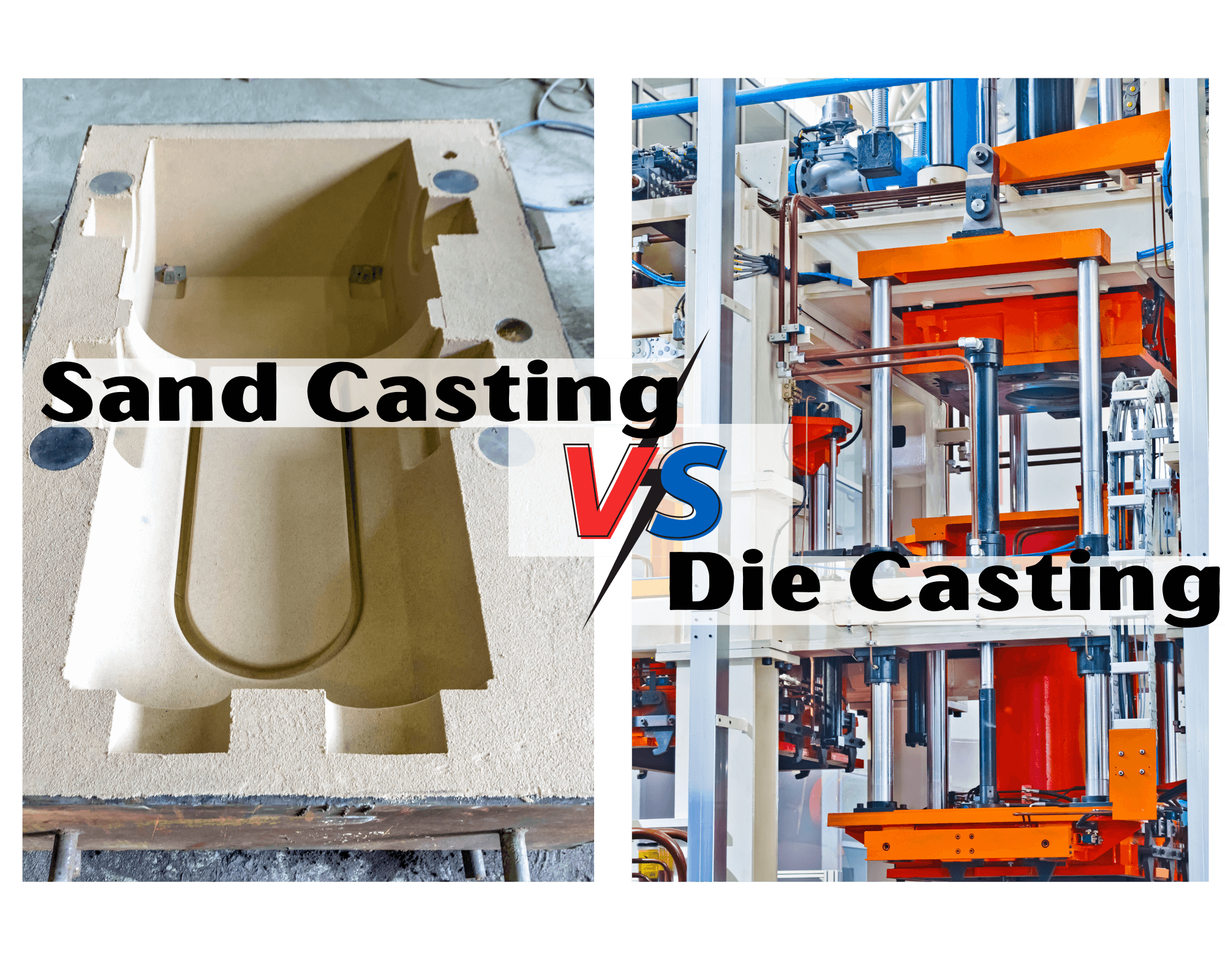

The sand casting process is an ancient art that has been used for thousands of years. The basic principle of sand casting is simple - a pattern is made of the component to be cast, and sand is packed around the pattern. The pattern is then removed, leaving a cavity in the sand. Molten metal is poured into the cavity, and the sand is allowed to cool and solidify around the metal, creating a solid metal component. The final product can then be machined or finished as necessary.

Sand casting is a flexible and versatile process that can be used to create components of virtually any size and shape. The process is particularly suited to producing large, irregularly shaped parts with complex features. This makes it a popular choice for many industries, including the automotive, aerospace, agricultural, and industrial sectors. The process can be used to produce both ferrous and non-ferrous metals, including ductile iron, gray iron, and compacted graphite iron (CGI).

Ningbo Yinzhou Ke Ming Machinery Manufacturing Co., Ltd., is a leading supplier of investment castings with water glass process in China. The company specializes in the production of lost wax investment castings, which are made by creating a wax pattern of the component to be cast. The wax pattern is then coated in a ceramic shell, which is baked to harden the shell and melt the wax. The cavity left by the wax is then filled with molten metal, creating a solid metal component.

Investment casting is a precision process that can produce components with excellent accuracy and surface finish. The process is particularly suited to the production of small and medium-sized parts with intricate or complex shapes. Investment casting is ideal for producing high-strength components with thin walls, such as turbine blades, impellers, and other aerospace and automotive components.

Ningbo Yinzhou Ke Ming Machinery Manufacturing Co., Ltd., has many years of experience in the production of investment castings. The company's investment castings with water glass process are widely used in a variety of industries, including the aerospace, automotive, marine, and energy sectors. The company's investment casting process produces high-quality, precision parts with excellent surface finish and dimensional accuracy.

In conclusion, sand casting and investment casting are two of the most popular manufacturing processes used to produce complex and high-value-added components. Sand casting is ideal for producing large, irregularly shaped parts with complex features, while investment casting is perfect for producing precision components with excellent accuracy and surface finish. Ningbo Yinzhou Ke Ming Machinery Manufacturing Co., Ltd., is a leading supplier of investment castings with water glass process in China, and the company's products are widely used in numerous industries worldwide. Contact us today to know more about our services.